Product Overview

The Shark® is a computerized electronic measuring system that relies on ultrasound technology for dramatic productivity improvements and the industry’s best speed and accuracy. The Shark provides “measure-as-you-pull” functionality that virtually eliminates costly rework.

The Shark will enable you to:

- Get accurate measurements the first time, every time.

- Monitor up to 12 live measurement points and see results as you pull.

- Save time and money by avoiding rework and stopping to fix hidden issues.

Click on one of the section titles to learn more about the Shark Frame Measuring System.

Features

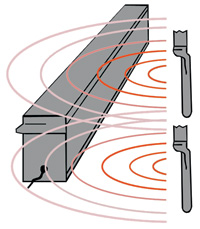

Award-Winning Ultrasound Technology

The Shark uses ultrasound technology to collect measurements and track your repairs. Probes with emmiters are attached to the vehicle at specific points and sent ultrasonic signals that are received by high frequency microphones located in the light-weight extruded aluminum beam. The results are compared to manufacturer specifications and any problem areas are identified automatically. This leaves the operator free to concentrate on straightening, not on how to collect measurements.

How the Shark Works

- The Shark relies on microphones located in the beam and ultrasound emitter probes placed at pre-defined points on the vehicle

- The beam is made of light-weight aluminum, goes anywhere, and is light enough for one technician to handle

- The Shark does not require a level rack, level car or level beam

- The technician has the option of viewing digital images of each attachment point and following the step-by-step guides for connecting accessories and probes

- The probes can be placed closely together and still maintain accurate readings - a feature not found on competitive systems

- The Shark console provides a live depiction of these control points and their variance from manufacturer specs with vivid, easy-to-read graphics

- During repair, these measurements are displayed as they change, allowing for extremely accurate, "right the first time" pulls and eliminating the back-and-forth process associated with competitive models

- Upper-body and under-hood measurements are obtained with ease using the included accessory, eliminating the need for any mechanical measuring devices or bridges

- An optional, second upper-body measuring accessory further improves job times

- Before and after-repair measurements are captured for reporting purposes

- PDF’s can be saved and e-mailed to the customer’s insurance company

Productivity-Enhancing Features

Vehicle Dimension Data

Onboard access to our Edata electronic vehicle dimensional point to point specifications on the vehicles window, door and truck openings along with A, B and C pillars.

Increased Profit Potential

Maximize your profit potential by using the Vehicle Pre-Delivery Checklist to offer services beyond collision repair.

Shop Information

Maintain consistency with OEM specs, view Techinical Service Bulletins and access vehicle repair information from OEM’s worldwide via the Shark®.

Custom Reports

Customize reports to meet your shop’s and insurance company’s requirements. View and print a quick comparison of the vehicle damage versus its repair, add vehicle damage pictures and repair notes, and build up a damage or repair unit estimate!

Optimized Storage

Poyurethane foam inserts with embossed accessory identifiers for storage location of accessory

Live Measurement Display Options

Live measurements enable real time feedback of your pulls, saving time and putting more money in your pocket. Three available display options of these measurements cover every technician’s preference. High visibility display lets you focus on only the control points with damage. Graphical XYZ displays length, width and height deviations individually. The pull angle displays the direction of the pull that would be made to correct the damage.

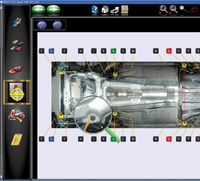

Attachment Points View

A technician favorite that improves productivity, view line art or actual vehicle images which display attachments points while the technician moves through the attachment process. The all new magnifying glass function allows the technician to zoom in on attachment points for an increased visual interpretation and make informative decisions in the repair process.

Additional Features

VIN Decoding, On-Screen Job Note Pad, Embedded and Context Sensitive Help Files, Multi-Layered Vehicle Graphics (Allows peeling and see-through functions), and On-Board Log (Tracks system maintenance, inventory audits).

Product Models

Platinum Model (EECR617B):

Hardware

- 12 Control Point - Live Active Measuring

- 360° Underhood Measuring Accessory (2 MCP’s)

- Premium Tool Box Cabinet with Premium Chrome Spoke Casters with Brakes

- Large, Wide Screen 27" LCD Display

- Premium Beam Storage and Mobility Cart

- Frame Rack Measuring Application Brackets

- Premium Cabinet and Beam Cover Kit

- VIN Code Reader

- Deluxe Tram Gauge

Software

Deluxe User Interface with the following productivity features:

- VIN Decoding

- Vehicle Image Database

- Point to Point Measuring

- Upper Body Opening Specifications

- Intuivie Help

Support

- Two Year Warranty

- Two Year Vehicle Specifications Subscription with Technical Support Hotline

Standard Model (EECR617C):

Hardware

- 8 Control Point - Live Active Measuring

- 180° Underhood Measuring Accessory (1 MCP)

- Premium Tool Box Cabinet with Standard Casters with Brakes

- Wide Screen 19" LCD Display

- Beam Wall Storage Brackets

- Frame Rack Measuring Application Brackets

- Standard Cabinet and Beam Cover Kit

Software

Standard fundamental Windows® program scheme for fast reliable results

Support

- One Year Warranty

- One Year Vehicle Specifications Subscription with Technical Support Hotline